What lies beneath

What lies beneath – using NDT of Superyachts

Brookes Bell is a leading international marine technical and surveying consultancy. Over the last 30 years the company has seen more and more of its skills developed in the cruise sector applied to the superyacht industry, as the team advises owners, captains, managers, designers, engineers and shipyards on newbuilds, rebuilds and refits.

Arron Jackaman is a Senior Inspection Engineer who has worked in the heavy industry sector for 18 years, specialising in marine and offshore structures and plant installations encompassed in the field of Asset Integrity Management. Here, he talks about Brookes Bell’s non-destructive testing (NDT) services for the superyacht industry.

The issue has always been ‘what lies beneath’, i.e. underneath the coatings and coverings of a high value bespoke vessel, but until now it’s been so expensive and difficult to find out without damaging a significant part of the vessel as part of the investigation. It’s a headache for the owner and manager, as well as the shipyard undertaking the repairs. Neither side is able to accurately estimate the length of time out of water, or the resources – labour and materials – required, until the work actually begins.

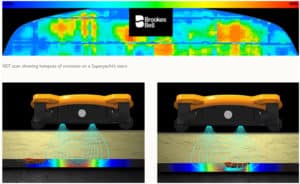

Brookes Bell is now using forward-thinking advanced NDT techniques for superyachts. One of these inspection methods uses pulsed eddy current (PEC) technology inside a probe to scan through a non-ferrous coating to accurately assess the state of the steel plate underneath. In effect, the probe can ‘see through’ and ignore a teak deck, paint, antifouling and cladding to gather data to create a Corrosion and Thickness Assessment (CTA).

The PEC Deck Scans can be done at up to 150mm per second with a scan width up to 450mm, meaning vast areas can be covered in a relatively short time. The system can use different detection sensors depending on the area, a large probe for bigger areas and a smaller probe for tight corners and side decks.

The final corrosion detection and measurement report is produced in an easy-to-read format that clearly shows the areas of concern that need treating or replacing. A simple colour spectrum provides a comprehensive and understandable ‘at a glance’ view as well as the detail needed to assess the size of the issue: with blue (good and sound) through to green, yellow and orange to red (bad, area for concern).

Launched in autumn 2019, the service was originally designed for steel. However, in a new development, the sensory array probe is being re-engineered to scan for aluminium defects too, and will be ready for summer 2021. Brookes Bell wants to be able to detect aluminium salts corrosion, along with other types of common problem such as cracks in aluminium deck plating.

Read more in the latest issue of PCE-International