The United Arab Emirates (UAE) has the second-largest economy in the Arab world. Cities like Dubai have become global business hubs, attracting expatriates from all over the world. The growing population comes with an increasing demand for housing and infrastructure as well as energy and water. The Wacker chemical group and Dubai Central Laboratories joined forces to set construction standards for sustainable, energy-efficient buildings in the region.

The construction sector is one of the key economic drivers in the UAE. In 2017, it contributed 8.4% to the country’s GDP. According to Research and Market, a market research company based in Dublin, the UAE construction industry is expected to rise at a compound annual growth rate of 4.64 percent during 2019-23. It is expected to hit $101.2 billion by 2023. With an expanding economy, a rise in population and climatic considerations, the demand for electricity and water continues to grow at a fast pace in the country.

According to Business Monitor International, a sharp increase in annual power demand throughout the UAE is expected over the period 2012-21, with an anticipated average annual increase in consumption of 5.6 percent. Increasing energy efficiency has therefore become an important goal of the UAE government. In 2017, the UAE launched Energy Strategy 2050, which aims to increase the contribution of clean energy in the total energy mix from 25 percent to 50 percent by 2050 and to reduce the carbon footprint of power generation by 70 percent, thus saving AED 700 billion by 2050. Under this strategy, the city of Dubai aims to produce 75 percent of its energy requirements from clean sources by 2050 and to become the most sustainable city in the world by 2020.

ENERGY FOCUS

Energy consumption in housing has become a particular focus of attention as people increasingly resort to air conditioning to create thermal comfort in interior spaces.

To tackle ever-increasing energy demands, the Wacker chemical group and Dubai Central Laboratories (DCL) launched a project that combats a main aspect of the problem: buildings made with energy-wasting construction materials. Wacker is headquartered in Munich, Germany. The company is one of the largest silicone manufacturers worldwide and a leading producer of binders and polymeric additives based on polyvinyl acetate and vinyl acetate copolymers and terpolymers. Its products are required in high-growth end-user sectors, such as construction, photovoltaics, electronics, pharmaceuticals and personal-care products. The group maintains production sites, subsidiaries and sales offices in 32 countries across the globe. Dubai Central Laboratories (DCL) is a Dubai government body that defines standards and implements quality control for sustainable living. It is a key stakeholder in establishing green building codes in the region.

The two organisations joined forces to introduce sustainable building solutions and establish international construction standards in the Middle East. To this end, they conducted a 12-month model-house study that began in August 2018. For the purposes of the investigation, two model houses were erected on the premises of DCL, under the supervision of DCL staff. Each house has a floor area of 6 m2, is 2.7 m tall and has an overall volume of 24 m3. The foundation walls and roof are built with standard light weight concrete. Wacker applications engineers from the Technical Center for Construction & Paints and Coatings did all of the application work in the houses, which were used for research and testing purposes. The two units provide a comparison between conventional and sustainable construction materials.

The conventional model house was not insulated, standard paint based on styrene acrylate was used on the exterior and interior, and the doors and windows were sealed with a standard sealant based on polyurethane. The sustainable house was insulated and built with Wacker enhanced products. The application of the building materials focused on three main areas: the exterior wall elements, the interior flooring and the interior wall.

EXTERIOR WALL ELEMENTS

Exterior walls are the single largest source of leaks of hot or cold air in buildings.

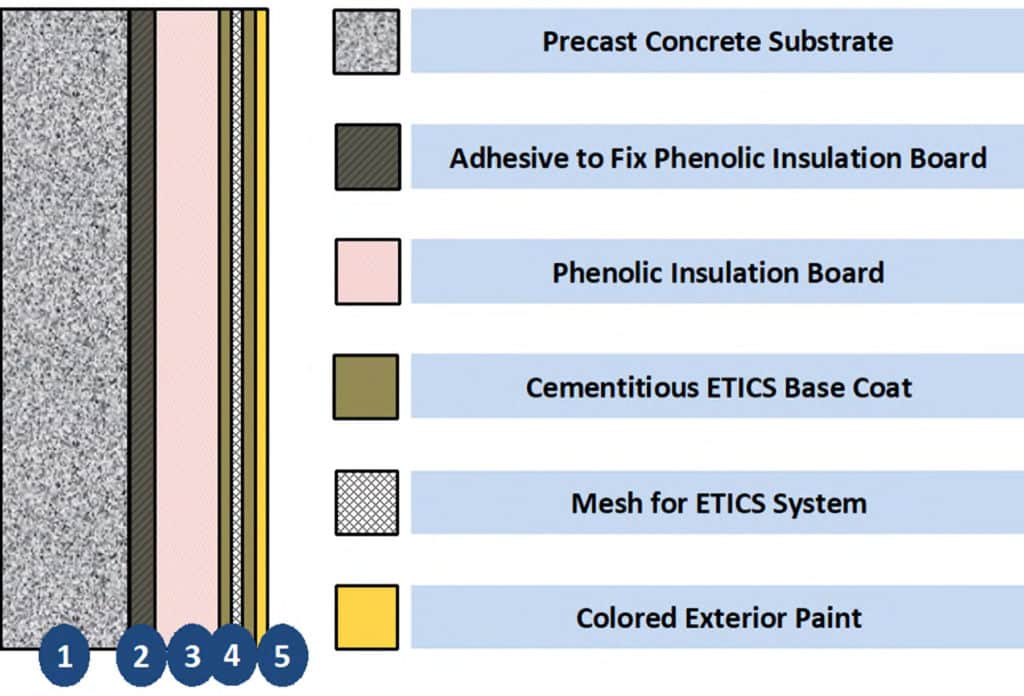

The most efficient insulation measure is an external thermal insulation composite system (ETICS, also known as EIFS for exterior insulation and finish system). Installing an ETICS in a single-family home or duplex, for example, can slash energy costs by as much as 60%. To install the system in the model house, Wacker experts applied adhesive to secure the phenolic insulation board on the wall. Then they added a cementitious ETICS base coat with mesh on the insulation board. The base coat protects the insulation board against weathering and provides mechanical strength. To achieve this effect, the base coat has to be flexible. When used as part of cementitious base coats, Wacker’s VINNAPAS dispersible polymer powders ensure this flexibility, contribute to good adhesion and provide protection against water.

Finally, exterior wall paint was applied on the facade to provide protection against moisture and harmful environmental effects. The paint is usually exposed not only to attack from external chemical, mechanical and biological sources, but also to attack from within the building material itself. The sustainable model house was painted with a silicone resin emulsion paint (SREP), which combines the outstanding properties of mineral paints with those of synthetic-resin paints. SREP paints show very high water- vapour permeability, very low water absorption and extreme longevity, thus actively helping preserve the value of the building’s structure.

FLOOR ELEMENTS

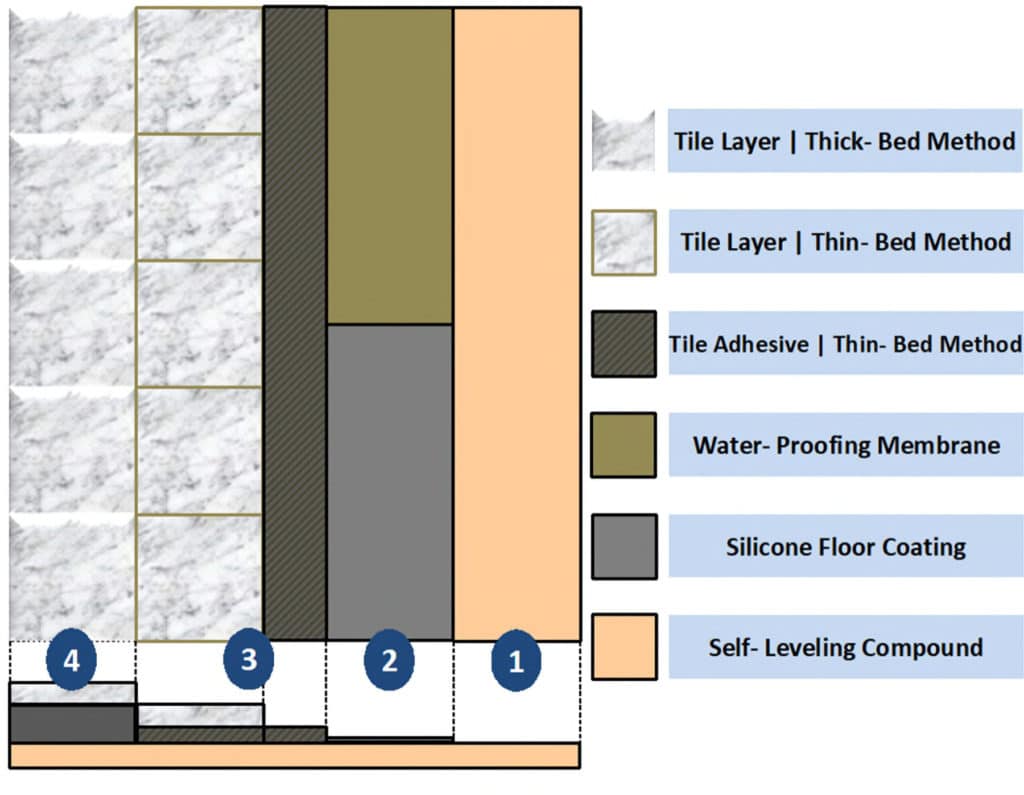

The insulated model house contains different flooring elements. Wacker experts built the first layer with a self-levelling compound. Polymer binders add functionality to self- levelling compounds: they yield void-free, smooth surfaces that resist abrasion, decrease hardening time, and can reduce the number of additives needed in the compound. A silicone floor coating and a waterproofing membrane were applied on top of the compound to protect the floor against damage and dirt, and to act as a water barrier. Tiles are the preferred flooring in the region and have therefore been laid in the insulated model house.

Floor elements of the insulated model house

Two installation techniques can be applied depending on the tile adhesive: thin-bed technology with polymer-enhanced tile adhesive and thick-bed technology with conventional tile adhesive. Polymeric binders improve how tiles adhere to the substrate, while permitting flexibility within the adhesive – an effective way of preventing cracks and breakage. These powders make the adhesive highly water- resistant and extremely easy to process. What is more, formulations containing polymer powders permit the thin-bed technology. This makes significant savings possible in terms of raw materials, such as cement or sand, the latter being a key raw material in the construction sector.

Exterior wall elements of the insulated model house.

The global construction boom means that sand is becoming increasingly scarce. INTERIOR WALL ELEMENTS For the interior wall elements, Wacker experts used a skim coat on the precast concrete substrate to create a flawless and smooth wall. Modern skim coats generally consist of cement, polymer binders, fillers and various additives. Polymer binders based on vinyl acetate-ethylene copolymers (VAE) improve the adhesion, flexibility and workability of the skim coat. The interior walls of the insulated model house were ultimately painted with a high- quality VAE-based interior wall paint. The polymer dispersion used for this paint is VINNAPAS EP 3360. Because it has a very low residual monomer content (< 200 ppm) and does not need organic solvents or coalescing agents to achieve optimum film formation, this product can be used for formulating low-odour, very-low-VOC paints (< 1g/L). Its odour profile is noticeably subdued, especially compared to standard styrene-acrylic or vinyl-acrylic technology, allowing rooms to be put to use more quickly. Furthermore, VINNAPAS EP 3360 is produced without the use of alkyl phenol ethoxylates (APEOs), and its formaldehyde content is very low (< 20 ppm), making it suitable for formulating paints that comply with major international ecolabels.

Finally, a weather sealant that complies with international green-building and sealant standards was used to seal external and internal connection joints at the door and window of the insulated model house. This one-part neutral silicone sealant adheres well on exterior joints, and is highly durable and resistant to weathering – important factors considering the extreme weather conditions prevalent in Dubai. To maintain the temperature inside the rooms, air conditioning units were installed in both houses. The air conditioners were programmed to run continuously to a pre- set interior air temperature of 23°C. Data was recorded continuously by DCL staff in order to establish the energy consumption, interior temperature and humidity, atmospheric temperature and humidity, and the total volatile organic compounds (VOCs) in both houses. TEST RESULTS After the one-year testing period, results show that the sustainable model house made with Wacker construction materials performed better than the house with conventional materials. The sealants on the windows and doors of the latter are cracked and have yellowed under the sun’s harsh ultra-violet rays, while the facade and seals of the sustainably built house are still clean, intact and blemish free.

By contrast, Wacker’s core-shell and exterior SREP (Silicone Resin Emulsion Paint) technology repels water and dirt extremely well, is breathable, hinders paint deterioration and reduces dirt pick-up by around 25%. Stepping inside, the water stains on the ceiling and walls reveal conventional materials’ inability to cope with precipitation from the outside and condensation from the inside. Additionally, results show that indoor air quality is significantly improved when VAE-based paints and silicon sealants are used. The VOC content of Wacker’s VAE technology-based interior paint is seven times lower than that of conventional paints as per ISO 11890-1. The enclosed figure shows the improvement of the indoor air quality measured over a period of eight hours in the actual condition of the insulated model house. Although air conditioners in both houses were programmed to run continuously to a pre-set interior air temperature of 23°C, the temperature in the non-insulated house increased significantly in the summer months, compared to the insulated house, in which the temperature generally remained consistent throughout the year. Additionally, results show that the energy- friendly model house featuring ETICS provides an impressive contrast to the non-ETICS house in terms of energy efficiency and carbon footprint: project results to date indicate a more than 60.5% drop in energy consumption and a 60% reduction in carbon dioxide emissions. Furthermore, when tested with polymer-modified cement, the thin-bed tile-adhesive application method was shown to require 55% less tile adhesive than the conventional thick-bed method.

OUTLOOK

The project was scheduled to be finished in September 2019. DCL has already begun using the study findings as a basis for revising the environmental and sustainability standards (Safaat) for construction materials. New standards are set to include application methods and specification based on the study results, especially those relating to ETICS and low-VOC paints.